Our Heritage Products

casted & robust design

casted & robust design

journal bearings

casted & keyed design

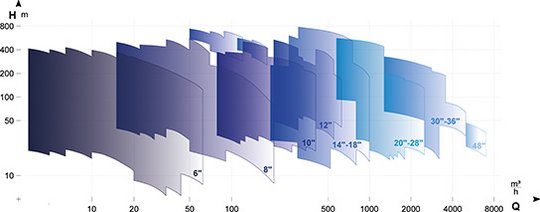

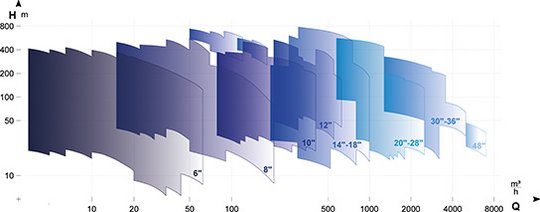

Companies worldwide use Pleuger’s submersible pumps in multiple applications across the water, marine & offshore, oil & gas and mining industries. With sizes from 4’’ to 50’’ Pleuger’s single- and multi-stage pumps fit every specification. Pleuger pumps have a global reputation as being highly reliable and durable, efficient to run and unwavering performance. Available as standard with water-filled submersible motors, or for bespoke applications with oil-filled motors, the pumps are designed to be maintenance free.

In addition to units in standard configuration, Pleuger also offers custom-made units to ensure the highest level of operational reliability and performance in all applications – within even the harshest of environments. Specifications include a variety of materials, from cast iron, bronze and NiAlBz, to stainless steel 316 and Super Duplex stainless steel.

Key Features:

- Highly efficient motors and pump hydraulics

- Maintenance-free and reliable

- Cost-effective lifecycle

- Drinking water safe

- Space efficient installation in wells

- Flood-proof

- Safe against freezing

- Reduced noise and vibration

- Range of material grades

- Optional installation accessories

- Optional Permanent Magnet Motor (PMM) technology

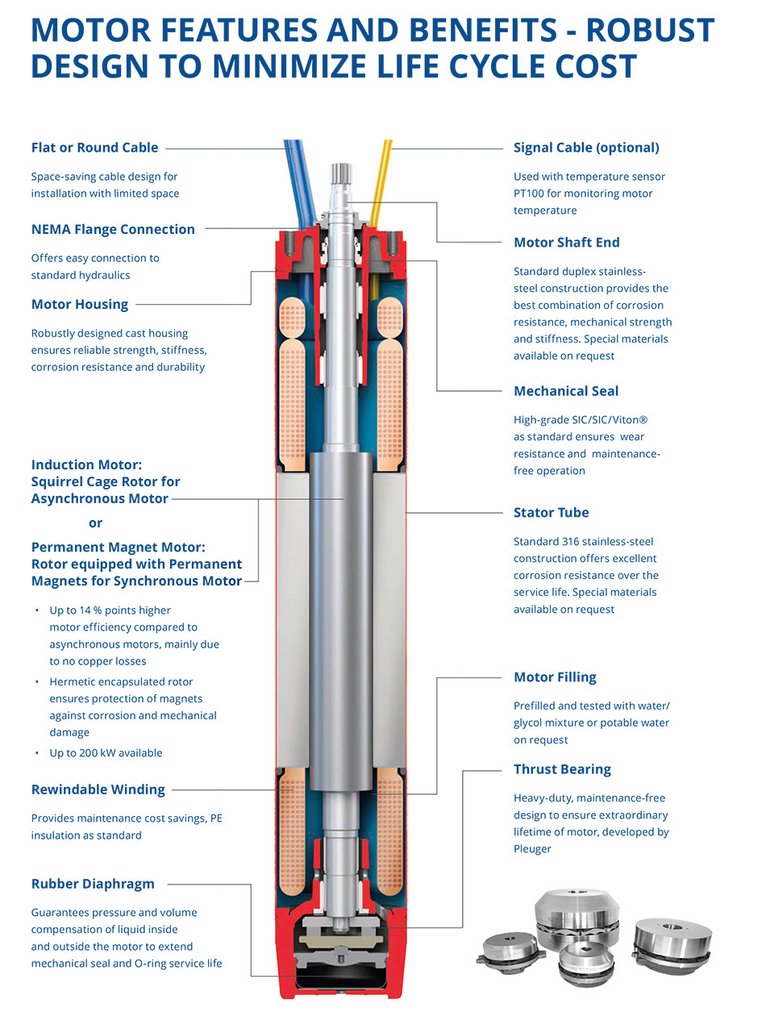

Motor Features and Benefits

As a manufacturer of world-class submersible motors, every product is designed, engineered and manufactured to the highest standards for efficiency, corrosion protection, and an extended power range. Our single- and multi-stage centrifugal pumps use either standard water-filled motors or oil-filled motors on request. Motor sizes are available from 4” to 50”.

Technical Specifications:

- Water-filled motors as standard

- Oil-filled motors on request

- Sizes: 4 to 50 inch

- Power output: 0.37 kW to 5 MW (0.5 HP to 6,700 HP)

- 230 V to 6.6 kV

- 3 PH – 50 Hz & 60 Hz

- 2 pole (standard) to 12 pole available

- Suitable for VFD operation

- Operating temperature up to 85°C

Standards:

- Design standards: NSF/ ANSI / ASTM / DIN / ISO / Hydraulic Institute / CE marking / API 610

- Hydraulic standards: ANSI/HI / EN ISO / API610 / NFPA20

- Electrical standards: NEMA / IEC / IEEE

- Certifications: DNV GL / ABS / CSA / ATEX

- Approvals: ISO 9001

(50 Hz), radial & semi-axial impeller

(60 Hz) radial & semi-axial impeller

Pleuger Permanent Magnet Motors

Highest Increase of Efficiency – Designed for maximal performance and reduced life-cycle costs.

Pleuger Permanent Magnet Motors (PMM) motors are rewindable, synchronous electric motors with a significant increase in motor efficiency up to 95% and power output. The PMM technology significantly lowers energy consumption, reducing costs and promoting sustainability.

Advantages and Benefits

- Up to 14 percent points better efficiency than asynchronous motors

- Designed to minimize life cycle costs

- Increased power output of more than 100% in comparison to asynchronous motors of the same size

- Flat efficiency curves drastically reduce the number of motor sizes needed

- Simplified storage

- Motors allow smaller unit sizes with reduced installation and storage costs

- Available as a standard customized solution

- 25+ design lifetime for the highest reliability

- Design based on the reliable Pleuger asynchronous induction motor

- Pleuger offers the complete system of pump, motor, and VFD

- No sinus filter or du/dt filter is required, reducing investment and energy cost

- Operated via variable frequency drive (VFD) ensures the most efficient operation

- Rewindable design

Technical Details

- 6” to 8”

- Synchronous motor

- Power output: 4 kW to 165 kW (5.36 to 221 HP), 200 kW (268 HP) on request

- Efficiencies up to 95%

- Operating speed: 2100 to 3600 rpm (max 3800 rpm)

- 4 pole design

- No particular VFD is required; standard VFDs from various manufacturers can be used

- VFD input voltage 400 to 500 V / 70 to 120 Hz

The perfect combination Pleuger PMM & Pleuger pump series PL06/08

Significant Savings in Energy Costs in combination with the Pleuger high-performance pumps PL06/08 available for 6” and 8” pump units with increased efficiency of up to 85% (average η opt > 83%).

Product Range

Built for a wide range of applications within the water, marine & offshore, oil & gas and mining industries.

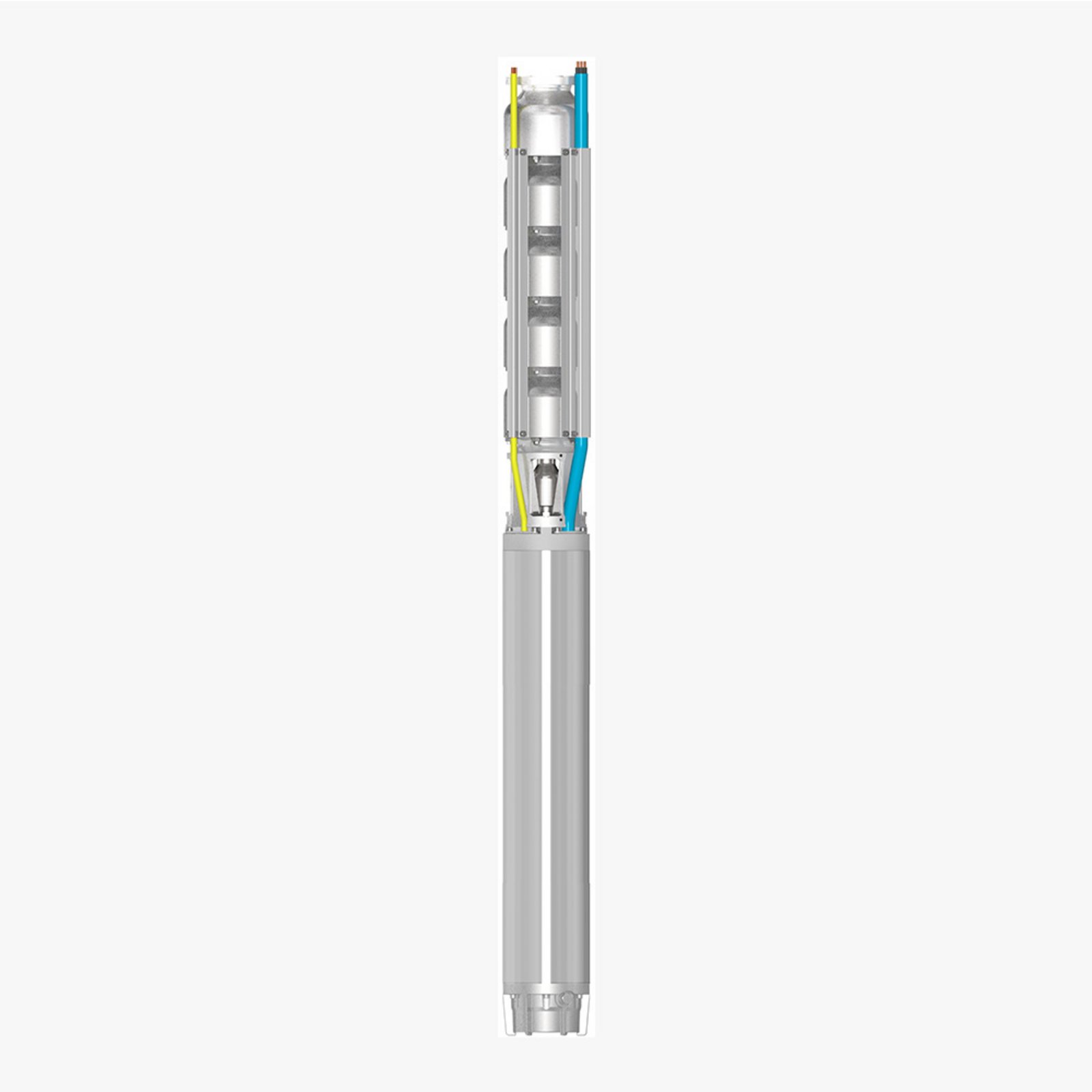

Deep Well Pump

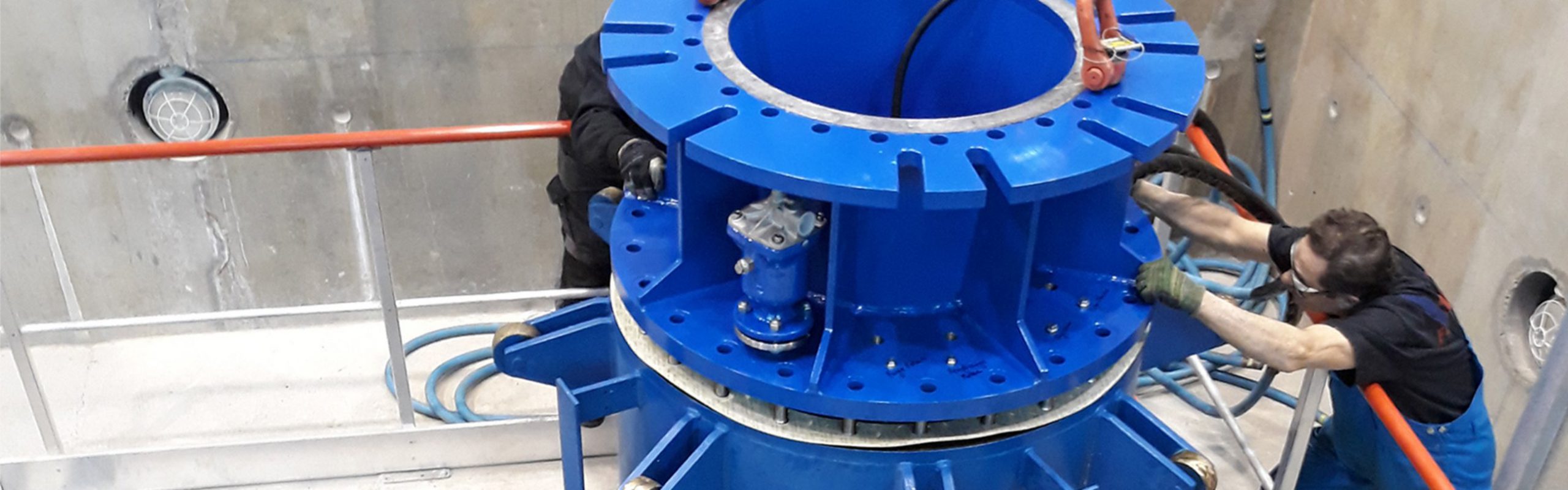

Cavern Pump

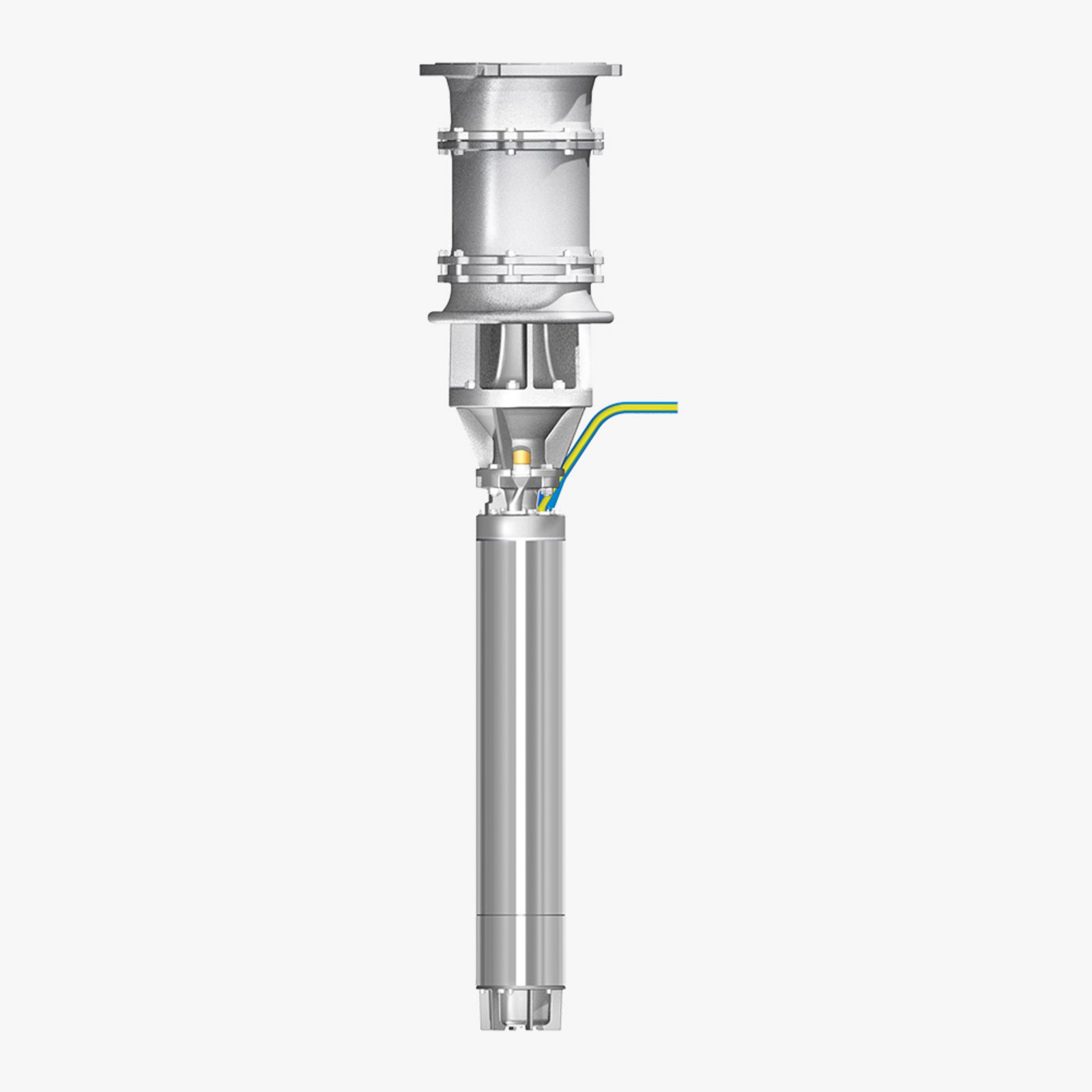

Bottom Intake Pump

The motor is placed above the pump, and the intake is in the pump’s lower section. This allows reduction of the water line to shallow levels. Bottom intake pump units can be designed for vertical or inclined installations and are available in standard configuration or engineered to order for specific requirements.