ALDRICH Reciprocating Pumps

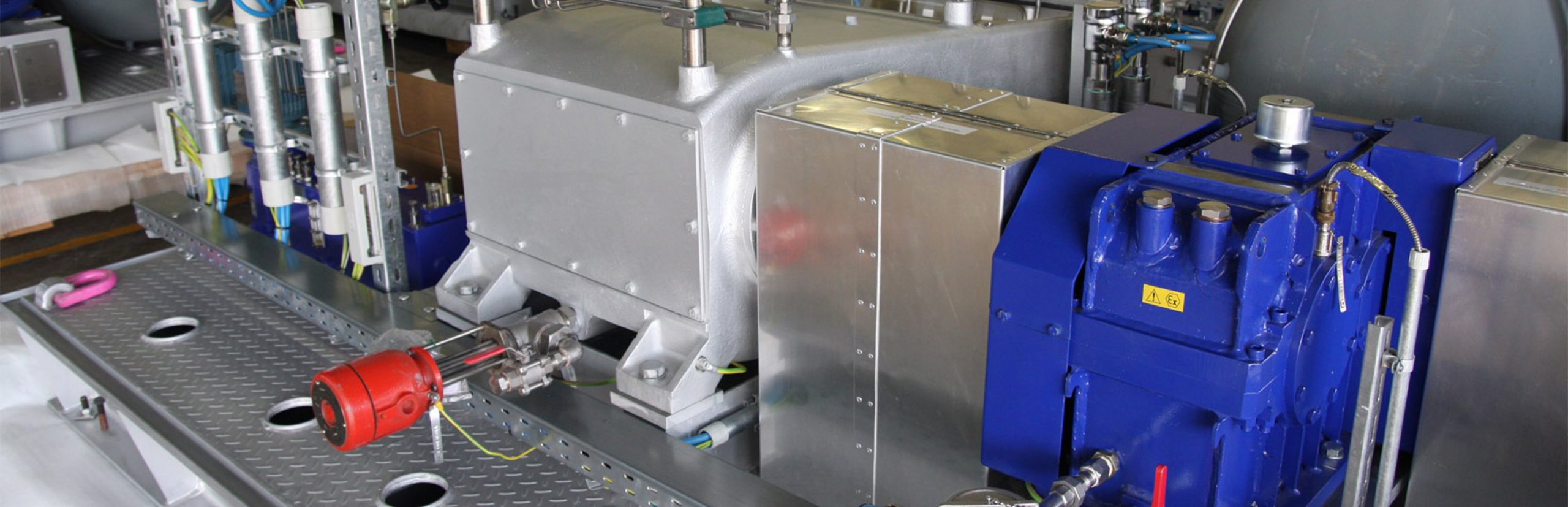

ALDRICH by PLEUGER is a leading manufacturer of Reciprocating Pumps and systems. The ALDRICH Reciprocating Pump range includes vertical and horizontal plunger pumps that meet the highest performance requirements. These high-performance, positive displacement pumps are designed for high loads and reliability, delivering a constant volume flow regardless of pressure.

ALDRICH Reciprocating Pumps are used in almost all industries worldwide and cover many tasks, including crude oil transport, pressurized water supply, hydraulic presses, descaling systems, and fresh and seawater injection in oil fields – both on land and drilling platforms.

As a manufacturer, PLEUGER offers ALDRICH units, Spare parts, and Services for global customers. Our products perform even in the most extreme and harshest of environments. That’s why the ALDRICH and the PLEUGER brands are renowned worldwide for quality and reliability.

WHEN TO USE A RECIPROCATING PUMP

- High pressure with low flow

- Variable flow with constant pressure

- Constant flow with variable pressure

- High efficiency required

MAIN ADVANTAGES

Reciprocating Pumps:

- Fixed flow per revenue

- Flow is independent of pressure

- Pressure is independent of flow

- High efficiency

Centrifugal Pumps:

- Varying flow per revenue

- Flow is pressure dependent

- Pressure is flow-dependent

- Low efficiency

ALDRICH RECIPROCATING PUMPS – A BRIEF HISTORY

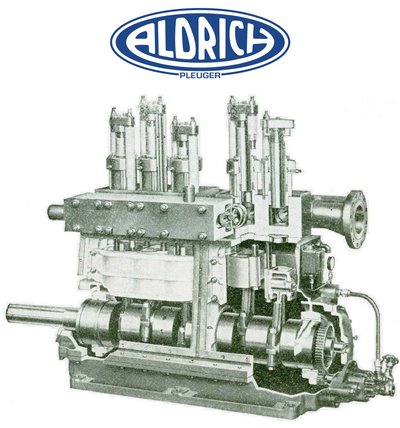

ALDRICH Reciprocating Plunger Pumps are inherently designed for reliable high-energy, heavy-duty service in specialized applications. Meeting API 674 design and performance criteria, each pump is engineered to provide continuous-duty operation over a 20-year design life. Offering a wide variety of hydraulic, mechanical, and materials options, ALDRICH Reciprocating Plunger Pumps can be constructed to meet the specific characteristics of the most demanding applications, including abrasive slurries and high viscosity liquids. This results in maximum operating flexibility with minimum life cycle costs.

ALDRICH MILESTONES

- Founded in 1902 as a division of Allentown Rolling Mills

- 1916 – direct drive for reciprocating pumps

- 1918 – high-speed pumps with 120 rpm crankshaft speed

- First in building Quintuplex Pumps

- 1939 – crankshaft operating speeds of 225 rpm Development of porcelain plungers

- First in developing Septuplex & Nonuplex Pumps

- Developed synchronized suction valve unloaders

Typical Applications

CHEMICAL

- Fatty Acid

- Fertilizer

- Ammonia

- Carbamate

- Reactor Feed (multiple chemicals)

- Detergent Production

OIL & GAS

- Crude oil Transport

- Slop Oil Transfer

- Methanol Injection

- MEG / TEG Gas Drying

- LPG / NGL Injection / Export

- Secondary Oil Recovery:

- CO2 Injection

- Steam flood

- Saltwater injection

- Hot Oil Services

INDUSTRIAL

- Reverse Osmosis

- Hydrotest

- Descaling

- Forging Press

- High-Pressure Cleaning /

- Blasting

MINING

- Dewatering

- Slurry transport

- Ore removal

- Iron / Nickel Ore

- Copper Concentrate

- Coal

- Hydraulic (high pressure water)

POWER

- Charge [Nuclear PWR]

- Boiler Feed (small boilers)

- Start-up / Standby Boiler Feed (large boilers)

- Hydro test

- Seal Injection

PUMP CUSTOMIZATION

The ALDRICH engineered Reciprocating Pumps offer users a wide range of options to customize a solution for mission-critical pumping needs.

The ALDRICH Reciprocating Pump product line provides maximum operating flexibility. Available in horizontal and vertical configurations and customer-specific materials. ALDRICH reciprocating pumps are engineered individually to meet the application’s actual performance and installation requirements while reducing maintenance and replacement costs.

KEY FEATURES

- Vertical and horizontal configurations

- Sectionalized or monobloc liquid ends

- Triplex, Quintuplex, Septuplex and Nonuplex plunger Configurations

- Various plunger size/stroke combinations

- High-temperature, high-pressure & slurry designs

- Custom pressures for continuous duty pumping to 2070 bar (30 000 psi)

- Wide range of liquid end stuffing box and power end sealing arrangements, including high-temperature or environmentally hazardous services

- Wide choice of drive trains

- API 674 certified

Various Design Options

Liquid end Design Options

Depending on the application, ALDRICH plunger pumps use different pump ends and corresponding cylinder designs. The slurry pump end has been specially developed for pumping media containing solids such as minerals, ores, overburden, and coal. The solids’ content can be up to 60 % by weight.

Pump cylinders with a minimum of clearance volume are the economical solution for pumping liquid gases such as ammonia, CO2, LNG, and LPG. Minimizing the clearance volume is an essential method for improving the volumetric efficiency of pumping compressible media. This applies not only to process pumps but also to secondary recovery into caverns and oil fields.

Design of the Cylinder Block

The monobloc construction of the cylinder block is convincing due to its high operational reliability. This one-piece construction with internal suction and discharge channels ensures individual accessibility to the valves without disconnecting suction and discharge connections.

The multi-part design of the cylinder block is designed for exceptional operating conditions, such as very high media temperatures. Suction and discharge manifolds connect the individual cylinder blocks. Depending on the requirements, forged or cast cylinders are built-in.

Stuffing Boxes

The stuffing box designs are adapted to the different media. Plungers in different material designs matched to these media contribute to the reliable operation of the machine.

Valves

A wide range of different valve variants in ball, plate, cone, or plug design is available for the various applications, ensuring reliable, low-maintenance operation.

Technical Features of Horizontal Plunger Pumps

- Plunger size: 25 mm up to 250 mm Plunger (1 to 10″)

- Flow rate: up to 800 m³/h (3,500 GPM)

- Power: up to 2,500 kW (3,350 HP)

- Discharge pressure: up to 550 bar (8,000 PSI)

- Discharge pressure in special cases: up to 2000 bar (30,000 PSI)

- Temperature: from -40°C to 350°C (-40 to 660°F)

- Speed: up to 530 RPM

The stated values are orientation values and can be adjusted according to the required operating conditions.

Technical Features of Vertical Plunger Pumps

- Plunger size: 38 mm to 229 mm Plunger (1,5 to 9″)

- Flow rate: up to 1,100 m³/h (5,000 GPM)

- Power: up to 3,450 kW (4,600 HP)

- Discharge pressure: up to 600 bar (9,000 PSI)

- Discharge pressure in special cases: up to 2,000 bar (30,000 PSI)

- Temperature: from -40°C to 350°C (-40 to 660°F)

- Speed: up to 360 RPM

The stated values are orientation values and can be adjusted according to the required operating conditions.

ALDRICH Aftermarket & Services

ALDRICH RECIPROCATING PUMPS RELATIONSHIP DRIVEN SERVICE, EXCEPTIONAL SUBJECT MATTER EXPERTISE, DELIVERED AROUND YOUR NEEDS.

The ALDRICH support services cover all aspects of support and consultancy that might be needed during your installation’s life cycle. ALDRICH Pumps are designed for extended service life, often running for decades. If you need spare parts for your ALDRICH product or system, you can obtain these quickly anywhere in the world.

ADVANTAGES OF THE ORIGINAL ALDRICH SERVICES

- Experts in the reliability of pump systems

- Decades of market and application experience including Oil & Gas, mining, water, and general industries

- Dedicated support team

- A global reputation for reliability and commitment to maximising the reliability and availability of customer equipment

- Worldwide network of support partners

- Equipment installed in over 100 countries

ORIGINAL SPARE PARTS

- Readily available parts for regularly scheduled maintenance and emergency callouts

- Latest standards

- Guaranteed quality and performance

- Stock and manufacture spare parts for heritage pumps no longer produced but still operational

REFURBISHED PARTS

- Accredited inspections to refurbish where viable

- Refurbishing of core pump components such as casings, hydraulics, and electrical parts

REVERSE-ENGINEERED PARTS

- Accredited inspection procedures

- Re-engineering where different performance is required

- Obsolete parts from other reciprocating manufacturers

- State-of-the-art scanning and computer modeling capabilities ensure any reverse-engineered product meets or exceeds the original specifications.

KITTING SERVICES

We can supply many component replacements in kit form, making it easy to purchase, ship, service, and remove the need for pre-assembly.

REPAIRS & OVERHAULS

ALDRICH’s repair facilities provide world-class support through our international master service centers as well as our service partner network. Our professional and highly skilled staff are ready to support anywhere in the world.

Reciprocating Pumps, due to their nature of the operation, can require considerable spare parts stock for routine maintenance, power-end, and liquid-end components.

These typically consist of:

- Components required for a complete pump overhaul typically include:

- O-Rings for all liquid end metal to metal face seals

- Stuffing box packing, plungers, and bushes

- Valve components and assemblies

- Crosshead extension rod seals (for horizontal pumps)

- Crankshaft seals

- Inspection cover gaskets

Components required for a complete pump overhaul typically include

- Pull/side rods [vertical pumps]

- Liquid cylinder gaskets [vertical pumps]

- Power end bearings [horizontal and vertical pumps]

EQUIPMENT LIFE EXTENSION

Recognizing that plants are being operated beyond their original design intent, we offer our customers Equipment Life Extension reviews to validate the continued operation of plant equipment past the original design life.

SYSTEM EXTENSION

ALDRICH can provide different solutions to upgrade your system, e.g., electrical control, motor protection, soft starter, to improve service intervals and extend the lifetime.

UPGRADES

PERFORMANCE. EFFICIENCY. LIFETIME EXTENSION.

ALDRICH upgrades ensure the ongoing performance and reliability of your equipment. We help protect the value of your assets through upgrades to minimize capital expenditures and maximize performance and reliability.

Upgrade capabilities

- Component material and design upgrades

- Performance increase upgrades

- Extended service intervals

- Complete revamps

ENGINEERING SERVICES AND SYSTEM CONSULTANCY

Our Engineering department is on hand to help you with your engineering challenges, including feasibility studies, design proposals for new installations or plans to remodel, expand or upgrade existing reciprocating pump systems.

ON-SITE SUPPORT AND INSTALLATION

As the reliability experts in reciprocating pumps and motors, we provide sound engineering expertise and specialist advice.

INTERNATIONAL SERVICE TEAM

- Installation planning and on-site support at customer sites

- Project management

- Supervision of installation to start-up and commissioning

- Extensive training at our service centers

We recommend using PLEUGER field service technicians to ensure all the connections and control systems are set up correctly for a stable and reliable operating system from the outset.

INSTALLATION AND SUPPORT CAPABILITIES

- Installation supervision and planning

- Inspections

- Installation supervision

- Start-up and commissioning support

- Worldwide support and project management

DEDICATED SUPPORT TEAM

Committed to solving problems and reducing downtime, the dedicated ALDRICH Care support team is there for you 24/7.

Rapid enquiry & quote service

For fast response and comprehensive quote please provide details.

We will contact you within as soon as possible.